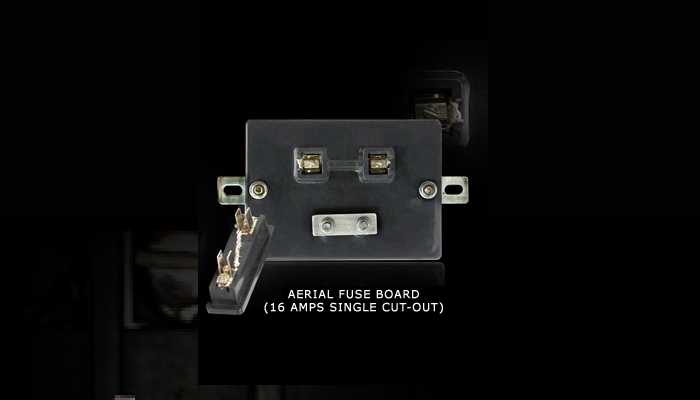

Terminal Block Assemblies

CT's operated Terminal Block Assemblies made out of phenolic moulding compound.

PRODUCT INFORMATION

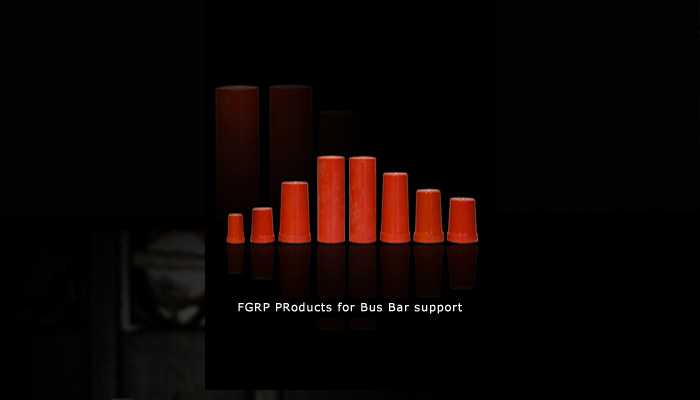

Category : |

Phenolic Moulding Compound. |

Grade: |

TEL 211/01. |

Features : |

Nylon Glass Fiber Reinforced Phenolic Moulding Compound with Low shrinkage, Good Machanical strength & High moisture Resistance, suitable for Compression Moulding. |

Application : |

Electrical Electronic. |

Components : |

Terminal Block Assembly for Energy Meter & Cover. |

Typical Property |

Method. |

Unit. |

Typical Value |

| Cup Flow, 4MT | TMP-02 |

seconds |

20 |

| Cup Curing Time | TMP-03 |

seconds |

120 |

| Cup Weight | TMP-04 |

grams |

30 |

| Tensile Strength | TMP-06 |

kg/cm2 |

530 |

| Flexural Strength | TMP-08 |

kg/cm2 |

780 |

| Izod Notched Impact Strength | TMP-09 |

kg.m |

0.028 |

| Dielectric Strength | TMP-10 |

volts/mm |

6500 |

| Surface Resistivity | TMP-11 |

log10 ohm |

11.5 |

| Volume Resistivity | TMP-12 |

log10 ohm.cm |

11.5 |

| Mould Shrinkage | TMP-13 |

% |

0.5 |

| Water Absorption | TMP-16 |

mg |

20 |

| Special Gravity | TMP-33 |

---- |

1.41 |

| Apparent Density | TMP-37 |

grams/cc |

0.45 |

CT Operated Terminal Block Assembly for Energy Meters made out of Phenolic Moulding Compound.

Sl No. |

Product Ratings & Capacity |

01 |

2.5 - 10 AMPS. |

02 |

5 - 20 AMPS. |

03 |

3X5 - 20 AMPS. |

04. |

3X10 - 40 AMPS. |