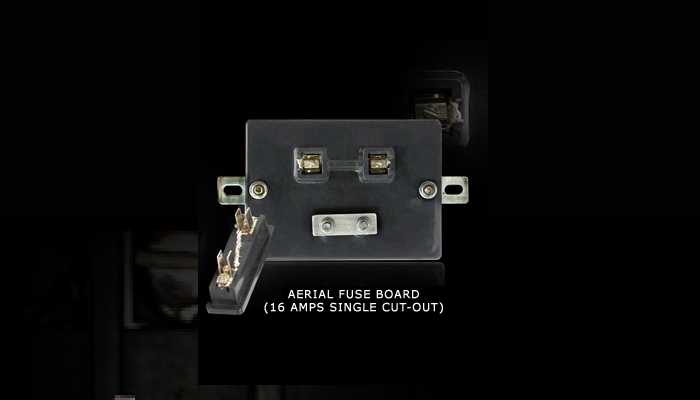

Pole Mounted FGRP (SMC) Aerial Fuse Boards

We manufacture 10 To 100 AMPS SMC Aerial Fuse Board with Cut-outs of 1 Way, 3 Way, 4 Way, 5 Way, 6 Way, 60 AMPS 3 way & 100 AMPS 3 way.

Features & Advantages

RANGES AND RATINGS OF FGRP (SMC) AERIAL FUSE BOARDS WITH CUT-OUTS

SI.NO |

Product Ratings & Capacity |

Product Name. |

|---|---|---|

1 |

10-22 Amps. | 1 Way Cut-out FGRP Aerial Fuse Board. |

2 |

30 Amps. | 3 Way Cut-out FGRP Aerial Fuse Board. |

3 |

30 Amps. | 4 Way Cut-out FGRP Aerial Fuse Board. |

4 |

30 Amps. | 5 Way Cut-out FGRP Aerial Fuse Board. |

5 |

30 Amps. | 6 Way Cut-out FGRP Aerial Fuse Board. |

6 |

60 Amps. | 3 Way Cut-out FGRP Aerial Fuse Board. |

RAWMATERIAL INFORMATION

SMC Aerial Fuse boards-Technical Specifications

PHYSICAL PROPERTIES

| Property | Testing method | Units | Specified values | Observed values |

|---|---|---|---|---|

| Density | BS-2782-PART 5-509A | Gm/cc |

1.70- 1.90 | 1.78 |

| Mould shrinkage | BS-2782-PART 6-640A | % |

0.15 – 0.20 | 0.18 |

| Glass content | BS-5734-PART 1 | % |

24 - 26 | 25.1 |

MECHANICAL STRENGTH |

||||

| Tensile strength | BS-2782-PART 3-320E |

Kg./Sq.cm | 750 | 770 |

| Flexural strength | BS-2782-PART 3-335A |

Kg./Sq.cm | 600 | 1,760 |

| Comp. strength | BS-2782-PART 3-345A |

Kg./Sq.cm | 1800 | 2,096 |

| Impact strength | BS-2782-PART 3-350 |

Kg./Sq.cm | 50 | 61.5 |

ELECTRICAL PROPERTY |

||||

| Vol. Resistivity | DIN-53482 | Log 10Ohm cm | 14 | 14 |

| Sur. Resistivity | DIN-53482 | Log 10 Ohm | 12 | 13 |

| Tracking index | DIN-53480 | volts | +800 | +800 |

| Di-Ele.strength | BS-2782-PART 2-201C | KV/mm | 12 | 12.7 |

| Arc Resistance | ASTM-D 495 | Second | +180 | 186 |

THERMAL |

||||

| Martens H.D.T | DIN-53462 | °C | +160 | +160 |

| Flammablity | UL-94 | VO | VO | VO |